A Beginner's Guide to Industrial Coffee Grinder Models

A Beginner's Guide to Industrial Coffee Grinder Models

Blog Article

Industrial Coffee Mill Overview: Boost Performance and Quality

In the competitive landscape of coffee production, selecting the right industrial coffee mill plays a crucial role in enhancing both effectiveness and product quality. Understanding the nuances of numerous mill kinds and essential functions-- such as personalized grind setups and durable building and construction-- can considerably influence the last taste profile of the coffee.

Recognizing Grinder Kinds

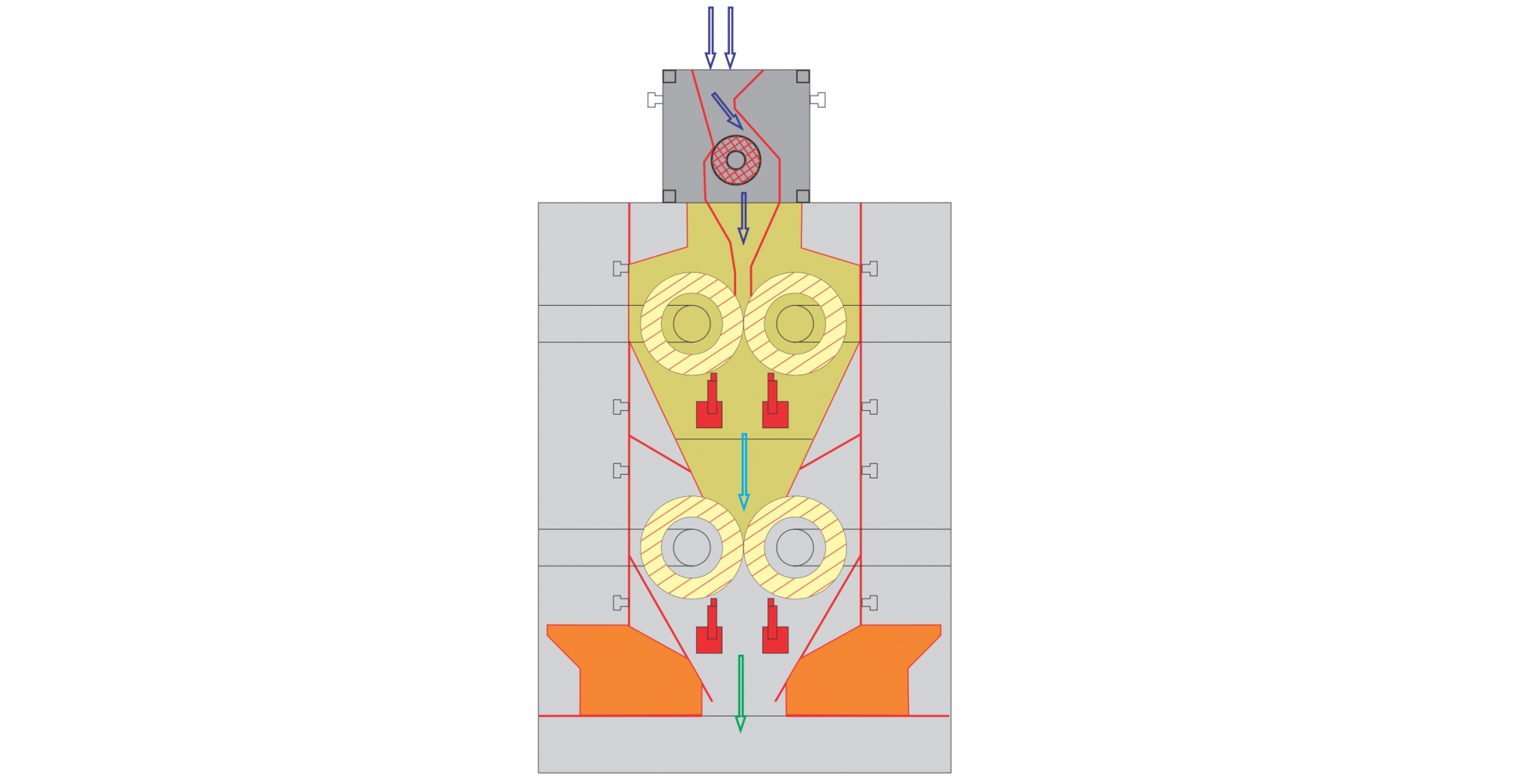

When selecting an industrial coffee grinder, comprehending the various kinds readily available is crucial for optimizing both flavor removal and functional effectiveness. The two key sorts of mills are blade grinders and burr grinders. Blade grinders utilize sharp blades that chop coffee beans right into irregular dimensions, resulting in irregular removal and possibly unfavorable tastes. While blade mills are commonly more budget friendly and suitable for small operations, they are usually not recommended for industrial use.

Inevitably, selecting the right sort of mill is important to maintaining high quality and performance in coffee manufacturing, making it important for businesses to invest in high-quality burr grinders for optimal results.

Trick Functions to Take Into Consideration

Choosing a commercial coffee mill needs careful consideration of numerous crucial functions that can considerably influence both performance and the overall coffee experience. One of the primary aspects to examine is the grinding system. Burr mills are generally favored over blade mills, as they supply a constant work dimension, which is essential for ideal removal and flavor.

One more vital function is the grinder's ability. A functional grinder with multiple setups permits you to tailor the grind dimension to various brewing approaches, enhancing the coffee's taste profile.

The building product also plays a duty in longevity and upkeep. Stainless steel parts frequently provide longevity and are easier to clean, which is important for preserving health criteria. Finally, evaluate the mill's noise degree, particularly in a busy café or manufacturing environment, where extreme sound can be turbulent. Purchasing a mill that stabilizes these features can substantially boost both operational performance and the top quality of the coffee served.

Optimizing Grinding Refine

To achieve the ideal outcomes in coffee preparation, enhancing the grinding procedure is essential. The work size significantly affects removal, flavor, and total top quality of the brewed coffee. Different developing methods require specific grind dimensions; for circumstances, coffee demands a great grind, while French press demands a coarse appearance. Understanding the relationship between grind size and brewing technique is the initial step in optimization.

Furthermore, keeping an eye on the grinding speed can maximize the procedure. Slower grinding frequently creates much less warmth, protecting delicate tastes and aromas. On the other hand, much faster grinding may create excessive heat, negatively influencing the coffee's high quality.

Maintenance and Treatment Tips

Correct maintenance and care of commercial coffee grinders are essential for making certain optimal efficiency and longevity. Routine cleansing is the structure of maintenance; residue accumulation can affect taste and grinding efficiency. It is advisable to clean up the grinder after each use, cleaning down the exterior and eliminating any kind of coffee grounds from the burrs.

Additionally, check the grinding burrs for damage. Boring burrs can endanger grind uniformity, so they must be replaced as necessary. Industrial Coffee Grinder. Occasionally adjusting the grinder is likewise essential, as this preserves the wanted work dimension for different developing approaches

Lubrication of moving parts need to be done according to the manufacturer's requirements, as this decreases rubbing and lengthens the life of the equipment. It is vital to utilize food-grade lubricants to make certain security and conformity with wellness laws.

Last but not least, maintain the grinder in a stable and dry setting to avoid corrosion and corrosion. By adhering to these maintenance and treatment suggestions, drivers can enhance the performance of their industrial coffee mills while guaranteeing top quality output and prolonged functional life.

Roi Analysis

Evaluating the return on investment (ROI) for industrial coffee mills is important for companies seeking to enhance their coffee production abilities. A comprehensive ROI evaluation aids identify the economic feasibility of spending in high-grade grinders, allowing businesses to evaluate the first expenses versus potential gains.

Analyze the acquisition rate of the mill, including installation and any needed modifications to existing why not try this out facilities. High-performance mills typically lead to minimized grinding time and enhanced throughput, which can considerably improve performance.

Additionally, take into consideration the effect on item quality. Industrial Coffee Grinder. Superior grinders yield an even more constant grind dimension, which can improve taste accounts and customer contentment, ultimately driving sales. By raising the quality of the last product, organizations can justify higher prices, bring about increased revenue

Conclusion

In summary, a commercial coffee mill plays a pivotal function in improving both effectiveness and item top quality within coffee manufacturing. By picking premium burr mills outfitted with vital attributes such as flexible grind setups and long lasting building and construction, organizations can make sure ideal flavor extraction. Routine maintenance is important for maintaining grinder performance and taking full advantage of client fulfillment. Eventually, the strategic investment in a trustworthy grinder contributes substantially to boosted earnings and competitiveness in the coffee industry.

In the competitive landscape of coffee production, picking the appropriate commercial coffee grinder plays an essential function like this in boosting both performance and item top quality. The 2 main types of grinders are blade mills and burr grinders. Within the burr grinder classification, there are flat burr mills and cone-shaped burr mills, each with its benefits. Burr i thought about this mills are typically preferred over blade grinders, as they supply a constant grind dimension, which is vital for optimal removal and taste.

In recap, an industrial coffee mill plays a crucial role in boosting both performance and item top quality within coffee manufacturing.

Report this page